Engineering and manufacturing fully-forged high-performance wheels is a complex process. All Apex wheels are engineered to deliver Real Performance, but there’s a lot that happens in the manufacturing process to bring those high-performance design concepts to reality. Real Performance guides our every step in crafting our forged wheels, from raw materials, all the way through our quality control processes.

Raw Aluminum Extrusions

Each Apex wheel starts with 6061 aluminum alloy that’s been extruded into a log-shaped form, then x-rayed for impurities. Next, a metallurgical analysis is done to confirm the composition and quality of the raw material used.

Extrusion Cutting

The extruded aluminum is then cut into smaller sections about one foot long and around 120 lbs each. These smaller sections are then pre-heated in an oven to prepare them to be loaded into the forging press.

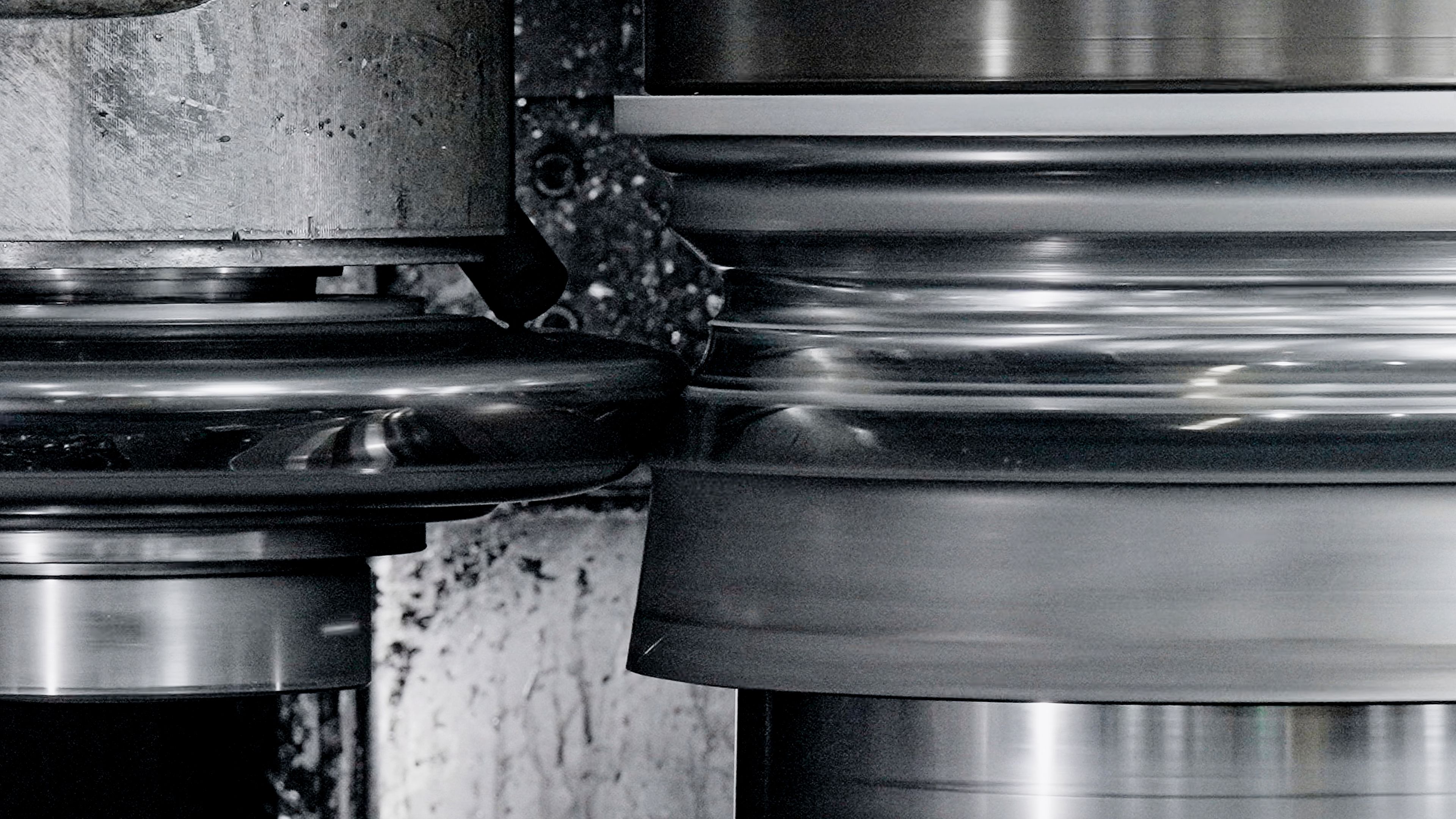

10K Ton Forging

The forging press applies 10,000 tons of pressure to shape the extruded aluminum into our motorsport blank profiles. This process is similar to stamping a coin and uses dies to form the aluminum into the desired shape. The incredible pressure applied during this step removes any porosity from the metal, making the aluminum denser and stronger.

Apex uses specialized motorsports dies to forge our wheel blanks. Designed by our engineers, these dies allow us to produce wheel designs with superior brake clearance, maximized concavity and spoke stiffness, and other key features that are not attainable when using cheaper, off-the-shelf blanks. When the forging process is complete, the blank is still heavy and the wheel’s barrel is thick and bell shaped.

Flow-Forming

Flow-forming is a process all monoblock forged blanks go through. In this step, the unformed barrel portion of a forged wheel blank is drawn down over a drum under intense pressure, which forms its respective width for that particular fitment. This step creates a dense barrel with the metal’s grain structure aligned in a radial direction for optimal strength.

We designed specialized drums that produce a final barrel profile with significantly more caliper clearance than traditional blanks, ensuring that we don’t have to compromise critical features.

Heat Treatment

After the blanks are flow-formed, they go through a 3-step T6 heat treatment process where the blanks are heated to an extremely high temperature for several hours, then put through a quenching process where they are rapidly cooled by submerging them in a liquid bath. The blanks are then artificially aged by reheating them for several hours and allowing them to cool naturally. This process maximizes the wheel’s material strength by improving the aluminum's mechanical properties.

Lathe-Turning

As the blanks enter this step, they still weigh around 120lbs each. Each wheel is lathe-turned to remove 40-50% of the excess material from the blank by finalizing the barrel profile and fundamental two-dimensional spoke profile, prepping the blank’s face for top-down machining.

While many wheel companies start with economy-focused wheel blanks that are made using off-the-shelf dies, Apex’s motorsport dies produce a blank with substantially more material in critical areas, allowing us to craft wheels with much deeper spokes, which is the key to creating much stiffer spokes.

CNC Face Machining

The lathe-turned blanks are then loaded into CNC machines where they are shaped into their final form. High-speed CNC machines are used to machine each wheel individually. Because our thicker motorsports blanks begin with substantially more material and because many of our wheels have intricate designs with complex side-milling, this step can take 6 or more hours per wheel.

CNC Side-Milling

The side-milling process is a key step to removing unnecessary material from the areas of a spoke that don’t add strength. A ball cutter is used to cut into the sides of spokes, transforming them from a crude rectangular shape into an I-beam or C-channel shape.

This process removes excess weight without compromising strength, and our computer simulations help us determine exactly where we can remove unnecessary material. Removing dead weight from the sides of spokes is a time-consuming and costly process, but it’s critical to making a weight efficient design.

This process takes hours of machining time per wheel, but it’s a key feature that sets Apex’s forged designs apart. When this step is complete, the wheel will have reached its final weight.

Surface Treatment

First, Apex wheels are hand-sanded to remove any burs or surface imperfections. Then the wheels are loaded into a vibratory grinding machine to ensure that the surface is prepared and uniform across the wheel. This process is extremely important for prepping raw wheels for a uniform and OEM-quality finish

Finish Coating

Apex wheels receive a 3-stage, OEM-equivalent coating process that includes applying a powdercoated primer base-coat, a liquid color coat, and a liquid clear coat. This creates a finish that not only looks fantastic, but will hold up to the rigors of legitimate track and street use for years. We ensure that no coatings are applied to the mounting surfaces as that can negatively impact securing the wheel to the vehicle.

Optional Brushing

Our brushed finishes are hand-applied by specially-trained technicians. This labor-intensive process requires the brushed finish to be carefully worked around the intricate curves and highly-detailed features of the wheel. The resulting look can only be achieved by hand-finishing and we think the results speak for themselves.

Laser Engraving

After painting, the Apex logo and the wheel’s specifications are applied to the inner lip of the wheel via laser engraving for easy reference and confirmation of specs.

Quality Control

All Apex wheels undergo an exhaustive quality control process, including runout and balance checks, dimensional inspection and gauging, radiographic inspection (also known as an x-ray check), pressure testing, and a final visual inspection for cosmetic flaws.

Packaging

Wheels are packed with a protective face cover and thick foam rim protectors, then carefully packed into heavy duty boxes to avoid damage in transit.

Frequently Asked Questions

Is a Forged Wheel Always Better than a Cast Wheel?

A common assumption is that just because a wheel is forged, its performance is superior to other wheel types. The reality is that while a forged wheel can deliver higher amounts of performance than other wheel construction methods, it needs to be engineered to do so. Not all forged wheels are legitimate high-performance products and “forged” is simply a construction technique, and not a catchall term for high-performance, as it is often used by other brands. A well engineered forged wheel is superior to a well engineered cast wheel of the same design. You need to watch out for companies that use the word “forged” to imply strength and superiority, while in actuality they may be corner cutting load ratings, testing, compromising stiffness, and delivering much less than expected.

Is Lighter Always Better?

Lightweight wheels are great, as long as they aren’t compromised elsewhere. That means safety, strength, and stiffness. A lightweight wheel that trades load rating and/or stiffness for weight-savings is ultimately robbing you of performance and grip when it flexes under load or fails. A wheel’s overall performance profile is about balancing these metrics, not just weight-savings. The industry is full of abuse with countless wheels compromised to be lighter on paper to catch a buyer’s eye.

Is the Wheel Industry Regulated?

Fact: The wheel industry in the US is completely unregulated. There are basic rules, but there is no active enforcement. No required testing. No audits. Buyers must put complete and absolute trust in the seller. This means not only can a brand sell a wheel without satisfying any safety regulations, it can make performance claims without any proof. If a brand isn’t backing their performance claims with data, those claims are probably not true.

Are Your Forged Wheels Actually Tested?

Many brands claim to test their wheels, but only use computer simulation to do so. Iterative FEA simulation is an important part of engineering a wheel, but it is no substitute for real world third party testing. Apex uses exhaustive FEA when designing a wheel, but all Apex wheel designs are also physically tested by the most stringent third party testing labs in the world, and we back those claims by including that info on every product page.

Shop Forged Wheels

Browse our current forged wheel designs below. You can click on any design to learn more and see available sizes and finishes. If you would like to compare designs, head on over to our Forged Wheels page and use the filters to help find the right fit.