Audi 8J TT RS Wheels

Lightweight flow formed wheels for your 2009-2014 8J TT RS

Lightweight flow formed APEX wheels for your 2009-2014 8J TT RS

4/4 Designs

Forged Sprint line

Forged Touring line

Flow Formed Evolution line

Finish: Anthracite

Overview

Audi 8J TT RS Wheel Performance

Despite having a Quattro AWD system, the factory Audi 8J TT RS wheel and tire setup can be a bit underwhelming at the limit. To maximize performance and increase the overall limit of grip, you will want to install a lightweight set of chassis-specific wheels in a wider fitment. With our Flow Formed SM-10 and Forged SM-10RS designs, we have plenty of options for just about all 8J TT RS applications. You can check out all of our fitment offerings for 8J TT RS wheels via our chassis specific 8J TT RS Wheel & Tire Fitment Guide

If you’re searching for 8J TT RS wheels, you’ve come to the right place! However, before you lock in your final fitment, design, and finish selections let's first take a quick look at the history of the 8J TT RS chassis.

The 8J chassis is technically the second generation of Audi’s TT coupe. However, the 8J was the first generation offered with Audi’s legendary RS nameplate and was sold from 2009-2014. Making its world debut at the 2009 Geneva auto show, the 8J TT RS was showcased in both coupe and roadster variants. Both body styles were equipped with Audi’s all-new 2.5l 5-cylinder turbocharged motor, pushing 335hp and 332 lb/ft of torque at the crank. Power was sent through a redesigned 6-speed close-ratio manual transmission mated to Audi’s Quattro AWD system, offering plenty of traction off the line and in low-grip situations. In 2010, an all-new 7-speed DSG transmission was offered as an option for the 8J TT RS through the rest of its life cycle. If you want to take full advantage of the 8J’s chassis and drivetrain, a fresh set of Apex 8J TT RS wheels in a wide and aggressive fitment will allow you to do just that.

The 8J TT RS has long been praised by enthusiasts for offering a potent drivetrain in a relatively compact and lightweight package. Paired with large factory brakes and optional magnetic-ride suspension developed in-house by Audi, there are plenty of aspects one can appreciate with these cars from the driver’s seat. Auto Express wrote up a decent review highlighting many of the pros, and some of the cons of the first generation TT RS.

SM-10RS Specifications

Reproductive Harm - www.p65warnings.ca.cov

Reproductive Harm - www.p65warnings.ca.cov SM-10RS features

10K Tons of Pressure

Our new forgings weigh as much as 120 pounds before machining. To form such a thick blank we require special equipment capable of 10,000 metric tons of pressure. This extreme pressure increases the strength of the aluminum by eliminating porosity and improving the grain structure.

True Motorsport Blanks

Many companies use 3rd-party blanks intended for non-motorsport wheels which can severely limit sizes, concavity, spoke design, and critical brake clearance. We designed our very own blank profiles from scratch to give us total control over the final product.

I-Beam Spokes

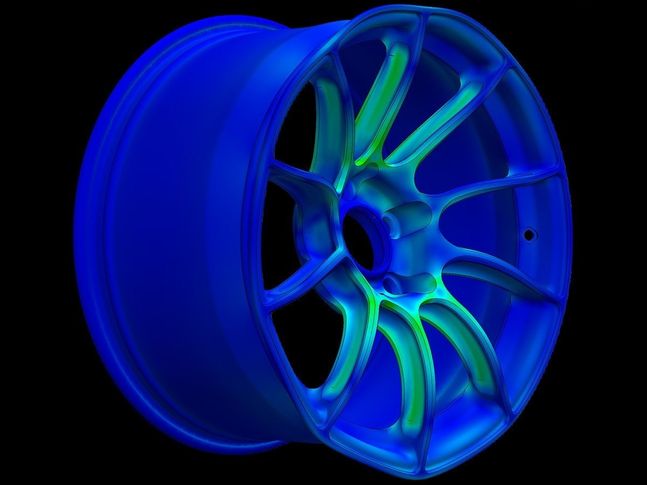

One of the most noticeable features of the SM-10RS is its use of side-milling on both sides of each spoke, creating an I-beam effect. Any excess material that doesn’t add strength is machined out using a precision CNC ball cutter. Side-milling is often deemed cost-prohibitive by others, but for true performance without compromise we believe it's essential.

A Stronger Lightweight Wheel

Our forged Sprint™ wheels are lightweight without the strength compromises found on typical lightweight wheels. First, we machined out as much material as possible, then we purposefully added one pound back to reinforce critical areas, creating a stronger inner lip and a higher load rating.² What’s the point of a lightweight wheel if it’s fragile?

Load Ratings (lbs)

JWL Load Standard

1521

Typical Forged Wheels

1521

Apex Flow Formed

1550

Apex Forged Sprint™ Line

1600

Weight Optimized

We conducted extensive Finite Element Analysis (FEA) to reinforce high-stress areas and to remove material where it didn’t improve strength. The result is a wheel that is exceptionally light without the strength compromises found on typical lightweight wheels.²

Wheel Weight

Load Rating

Apex Sprint™ Line

18 lbs

1600 lbs

Apex Flow Formed

21 lbs

1550 lbs

Greater Stiffness

The SM-10RS is not just another style to choose from. We used Finite Element Analysis of bending loads to optimize spoke geometry for greater stiffness without increasing weight. In fact, the SM-10RS is nearly identical in weight to our popular VS-5RS yet almost 10% stiffer, and 25% stiffer than our first generation of forged wheels.

Independently Tested

We don't rely solely on computer simulations or unverifiable in-house testing. We believe independent testing is critical to protect consumers in this unregulated industry. We chose STL, an independent lab in Ohio, to test our Sprint™ wheels far above JWL standards, including increases in testing duration, impact drop height, and total load.

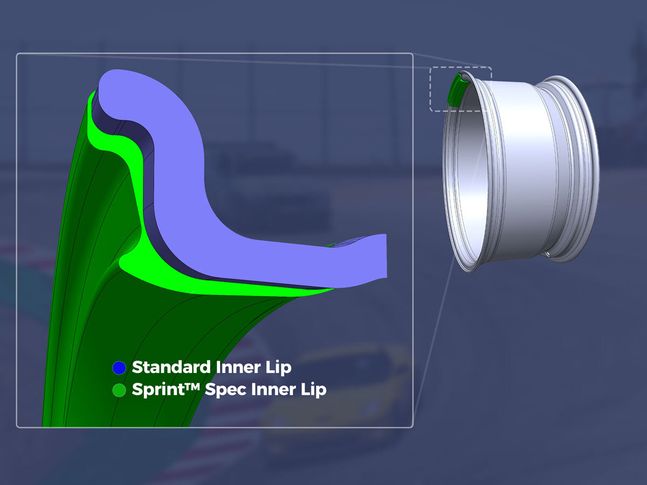

Tougher Inner Lip

Introducing the Sprint™ spec inner lip, with a unique channel profile that makes it even stronger than our previous designs. So even though our Sprint™ wheels are pounds lighter than comparable flow formed wheels, the inner lip is stronger.

32%

More reinforcement than our flow formed wheels3

Big Brake Clearance

From day one, Apex has been on a mission to build wheels that clear big brakes. Our new forged wheels are the product of everything we’ve developed over the past 10+ years, including an innovative high-clearance barrel design and vehicle-specific spoke profiles.

Deeper Concavity

Our new forgings were redesigned to create extra deep, concave spoke profiles. Their new shape allows us to make any profile, from flat to deep and everything in between. Each one is optimized for a specific application using 3D laser scans of factory and aftermarket brake kits.

Paintless Knurled Bead

Whether it's a day at the track or months of street driving, repeated hard braking and acceleration can make a tire slip along the bead seat and go out of balance, causing vibration. Knurled beads help, but are less effective when painted over. Our forged line features unpainted knurled beads that stay sharp and maximize grip.

Built for Impact Sockets

Track wheels need track tools. Don’t settle for wheels that require undersized tuner lugs or thin walled sockets. All Apex wheels accommodate over-sized race lugs and impact sockets to make swapping wheels lightning fast.

32mm

Socket Diameter Clearance

Laser-Engraved Specs

As track enthusiasts ourselves, we know how frustrating it is to try to locate and decipher wheel specs that have been hastily hammered into the rim or become unreadable over time. With our new Sprint™ wheels, we chose to invest a little extra and laser-engrave the specs on the barrel, in plain sight, making them easy to find and read. (You’re welcome.)

Additional features

Hub Centric

All SM-10RS wheels are purpose built for select vehicle applications. Very few applications require centering rings.

Center Caps

The majority of SM-10RS wheels come with a gloss black Apex cap which is interchangeable with your OE center cap*. Select JDM applications feature a capless center section. See vehicle product page for more details.

* Capless-center and centerlock wheels do not include Apex center caps. Certain unique fitments support an Apex center cap that is not interchangeable with the OE cap. See your vehicle-specific product page for additional details.

Wheel Hardware

Wherever possible, Apex wheels are designed to be used with OEM mounting hardware* as well as high-quality wheel spacers, stud conversion kits, wheel locks, and more. See our Accessories pages.

*A small number of applications use conical mounting hardware in place of the OEM ball seat hardware. Visit individual product pages to confirm hardware type/compatibility.

TPMS

All Apex wheels accept OEM and aftermarket Tire Pressure Monitoring Sensors and standard fit valve stems. If you don’t have sensors, then select from our metal stems available in multiple finishes.

REAL DRIVERS NEED REAL PERFORMANCE.

Not all claims of performance are backed up by facts—and it's a big problem. Don't get sold fashion when you want function.

A Wheel You Can Depend On

Accidental Damage Replacement

Curb rash or pothole damage on the street? Make an oopsie at the track? We’ve all been there. Apex is proud to offer 50% off replacement wheels, no matter the damage.

Lifetime Warranty

All Apex wheels come with a lifetime structural warranty against defects in workmanship and materials, plus a 1 year finish warranty. Exchanges are fast, easy, and hassle-free.

Footnotes

¹ VS-5RS vs. the original EC-7R, comparing side milling of 18x9” ET46 5x130 fitment.

² Strength and weight comparisons are based on an 18” BMW 5x120 wheel.

³ Comparing the amount of material reinforcement in our standard inner lip profile vs Sprint™ spec inner lip profile on an 18” wheel.

⁴ All wheels compared with equivalent 18x10” ET25 5x120mm / 72.56mm fitment. Price displayed based on MSRP as of 5/16/2025.

If you like cheap gear you will hate this newsletter.