Porsche 996 GT3 Wheels

Lightweight forged & flow formed wheels for your 1999-2005 996 GT3

Lightweight forged & flow formed APEX wheels for your 1999-2005 996 GT3

4/4 Designs

Forged Sprint line

Forged Touring line

Flow Formed Evolution line

Finish: Machined Lip Anthracite

Overview

996 GT3 Wheel Performance

The factory 996 GT3 wheels are very close in terms of their fitment but are much heavier than one would expect of the track oriented 996. If you want to maximize the potential of your GT3, a set of our lightweight chassis specific and lighter wheels will make a world of difference. We created Forged wheels such as the Apex EC-7RS and VS-5RS and our Flow Formed SM-10 to increase performance. Find out what fitment is best for your application in our Porsche 911 996 GT3 Wheel & Tire Fitment Guide.

A Brief History of the 996 GT3

While we offer wheels specifically for the 996 911 GT3 let's take a look at the first GT3, the one that started it all. This car was about saving weight, leaving behind the majority of sound deadening, rear seats, sunroof, and even air conditioning. Although A/C could be optioned back in at no cost. While the 996 Carrera engine was all new for the company, the 996 GT3 utilized the legendary Mezger engine known for its use in the 911 GT1 race car. This engine case was the one originally used in the air cooled 911s, early casting of this case on the 996 GT3 even shows a 964 part number. Despite being an older design this engine had major advantages over the Carrera’s M96 engine. With its integrated dry sump oiling system and lack of an intermediate shaft to drive the cams this was the far superior choice for anyone thinking about tracking their new 911. This same engine architecture was used for this generation's Cup Cars (Porsche factory customer race cars) which ran michelin slicks. The GT3 was equipped with a 6-speed manual transmission that can be linked back to the aircooled days instead of the unit found in the 996 Carrera. This was once again an advantage as that gearbox was more durable and was better suited to track use. At the end of the run in 2003 Porsche gave the rest of the world the first GT3RS. This was another homologation special from Porsche to assist the new RSR they were racing in sports car championships across the world. With new cylinder heads and wheel upright being the key components they were looking for, customers benefited by getting them in this wonderful street car. This included front strut top mounts that were reversible for additional camber as well as adjustable front and rear control arms.

Our wheels for the 996 generation 911 GT3 are shared between the GT3 and RS models as this was the first and only generation with shared bodywork widths between the GT3 and RS variants. The 18x9”ET46 and 18x11”ET60 are the go to sizes for this chassis which almost perfectly match the specs of the 996 GT3 Cup car. We typically recommend running the OE tire sizes on this setup but more options can be seen over on our 996 GT3 Wheel & Tire fitment Guide.

ML-10RT Specifications

Reproductive Harm - www.p65warnings.ca.cov

Reproductive Harm - www.p65warnings.ca.cov ML-10RT features

An Evolution of Performance

The ML-10RT honors the motorsport designs so many of us fell in love with during the golden era of Touring Car and Sports Car racing. However, its ancestry ends there. Our in-house engineering team pulled out all the stops to create a monoblock forged wheel that's lighter, stronger and stiffer than multi-piece wheels of the past. Utilizing the latest forging technology to offer an impeccable design, backed by Real Performance, at an obtainable price point.

Side-Milled Spokes

The ML-10RT incorporates Apex’s extra-deep, side-milled spokes. Any excess material that doesn’t add strength is machined out using a precision CNC ball cutter. Often deemed cost-prohibitive by others, this aggressive side-milling shaves critical weight, and adds a sharp contrast in the design of the center spoke area.

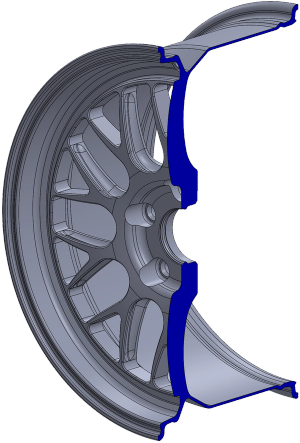

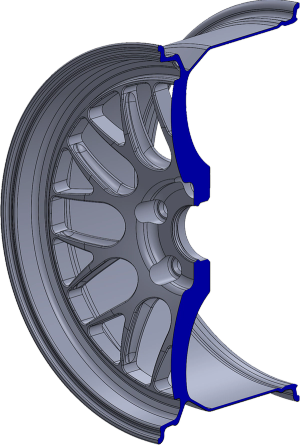

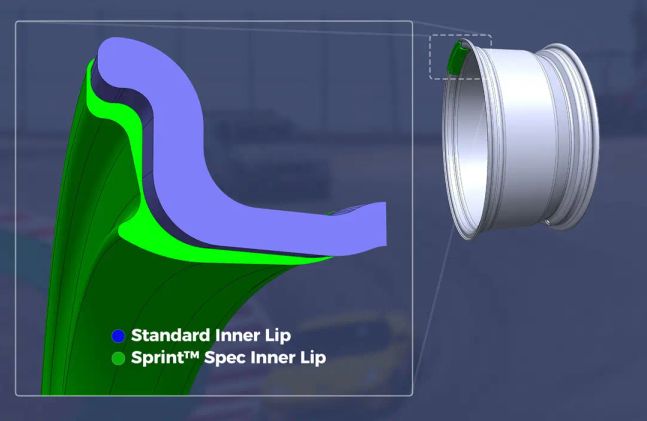

Sprint Inner Lip

The ML-10RT borrows the race-proven Sprint Spec inner lip from our Sprint Line wheels, providing critical strength to the unsupported inner lip of the wheel. Adding 32% more material where it matters most. Don’t settle for under-engineered wheels, attack both the track and your cities potholes with confidence.

50%

More reinforcement than a standard inner lip

10k Tons of Pressure

To make our forged wheels the strongest we can, we applied as much pressure as possible using a 10,000 ton forge. This extreme pressure increases the strength of the aluminum by eliminating porosity and improving the grain structure.

True Motorsport Blanks

Many companies use 3rd-party blanks intended for non-motorsport wheels which can severely limit sizes, concavity, spoke design, and critical brake clearance. We designed our very own blank profiles from scratch to give us total control over the final product.

Independently Tested

We don't rely solely on computer simulations or unverifiable in-house testing. We believe independent testing is critical to protect consumers in this unregulated industry. Our Touring Line wheels are independently tested by ITS at their Michigan facility following JWL standards but pushed to much higher loads and much longer durations.

Machined Lip

The ML-10RT is our first forged wheel to feature a machined lip, which really makes it a standout design within the Apex catalog. The lip in combination with the mesh center pays homage to the glory days of motorsport, and is sure to dramatically transform the look of any car. The best part - the machined lip has a gloss clear coat and doesn't require polishing. The ML-10RT features a consistent 1.5" outer lip across every wheel size, giving even our most conservative fitments the bold, deep-lip look enthusiasts love. Our more aggressive fitments then utilize the same 1.5” outer lip, and maximize spoke concavity for an ultra aggressive design profile while maintaining an aesthetic harmony with the thinner fitments often found on staggered applications.

Vehicle Specific Spoke Profiles

The lipped design of the ML-10RT inherently limits brake clearance. Rather than making every fitment as conservative as possible, we utilized our extensive 3D vehicle scanning library to shrink wrap each fitment's spoke design around respective OEM and popular aftermarket brake kits. Leveraging our vehicle research and engineering team, we find a perfect balance of concavity and brake clearance.

Built for Impact Sockets

Don’t settle for wheels that require undersized tuner lugs or thin walled sockets. All Apex wheels accommodate over-sized race lugs and impact sockets to make swapping wheels lightning fast.

32mm

Socket Diameter Clearance

OEM Center Cap Compatibility

Love that OEM+ look? Us too. Our engineers went the extra mile and incorporated a flush mounted OEM center cap support into the ML-10RT. Whether you want to show off your included Apex center caps or stick with your OEM caps, the ML-10RT will seamlessly accept both.

Laser-Engraved Specs

As car enthusiasts ourselves, we know how frustrating it is to locate and decipher wheel specs that have been hastily marked on a wheel or become unreadable over time. Our Touring Line wheels have laser-engraved specs on the barrel, in plain sight, making them easy to find and read.

Additional features

Hub Centric

All Forged Touring Line wheels are purpose built for select vehicle applications. Very few applications require centering rings.

Center Caps

All Apex Forged Touring Line wheels come with our gloss black cap included that is interchangeable with the OE cap. We also offer additional colors for select fitments.

Wheel Hardware

Wherever possible, Apex wheels are designed to be used with OEM mounting hardware as well as high-quality wheel spacers, stud conversion kits, wheel locks, and more. See our Accessories pages.

TPMS

All Apex wheels accept OEM and aftermarket Tire Pressure Monitoring Sensors and standard fit valve stems. If you don’t have sensors, then select from our metal stems available in multiple finishes.

REAL DRIVERS NEED REAL PERFORMANCE.

Not all claims of performance are backed up by facts—and it's a big problem. Don't get sold fashion when you want function.

A Wheel You Can Depend On

Accidental Damage Replacement

Curb rash or pothole damage on the street? Make an oopsie at the track? We’ve all been there. Apex is proud to offer 50% off replacement wheels, no matter the damage.

Lifetime Warranty

All Apex wheels come with a lifetime structural warranty against defects in workmanship and materials, plus a 1 year finish warranty. Exchanges are fast, easy, and hassle-free.

Footnotes

¹ All wheels compared with equivalent 18x10” ET25 5x120mm / 72.56mm fitment. Price displayed based on MSRP as of 5/16/2025.

If you like cheap gear you will hate this newsletter.