Audi 8V RS 3 Wheels

Lightweight flow formed wheels for your 2015-2021 Audi 8V RS 3

Lightweight flow formed APEX wheels for your 2015-2021 Audi 8V RS 3

4/4 Designs

Forged Sprint line

Forged Touring line

Flow Formed Evolution line

Finish: Anthracite

Overview

Audi 8V RS3 Wheel Performance

In stock form, the Audi 8V RS3 utilizes a reverse staggered wheel and tire setup. The main reason for this is to help alleviate some of the understeer characteristics common on a front-engined AWD chassis such as the RS3. While installing a wider square setup will neutralize the handling characteristics, making the car push a bit more at the limit, overall grip and cornering speed will be greatly improved at the same time. Plus, the ability to rotate your wheels and tires will allow you to maximize your tread life. If you want to fully take advantage of your 8V RS3’s chassis and drivetrain, a set of Apex 8V RS3 wheels in a wide and aggressive fitment will allow you to do just that. You can check out all of our 8V RS3 wheel offerings available in our Forged VS-5RS and SM-10RS designs, as well as our Flow Formed SM-10, via our chassis specific 8V Audi RS3 Wheel & Tire Fitment Guide.

History of the 8V RS3

Before you finalize your selection for a set of 8V RS3 wheels, let’s first take a dive into the history of the 8V RS3, and what has made it such a special car in the eyes of enthusiasts over the years.

The 8V RS3 made its first debut in late 2014 and hit dealership showroom floors the following year. The 8V RS3 is based on the third-generation of Audi’s A3/S3/RS3 chassis and sold through the model years of 2015-2020, with a mid-cycle refresh in late 2017. While the 8V RS3 was offered with two distinct body styles, a hatchback and a sedan, North American markets only received the latter. Regardless of body style, all 8V RS3s were equipped with a potent 2.5l 5-cylinder turbo charged motor, paired with a lightning-quick 7-speed DSG transmission. Power was sent to all four wheels via Audi’s legendary Quattro AWD system, making for incredible traction off the line and in limited grip situations.

8V RS3 Chassis Dynamics

The 8V Audi RS3 is factory-equipped with massive 8-piston 370mm front brakes and a 19" wheel and tire setup in a reverse-staggered configuration. While the standard reverse-staggered setup provides the car with fewer understeer characteristics out of the box, the lack of being able to rotate the wheels and tires makes it less than ideal for track use. Taking into consideration the Quattro AWD system and front-biased weight distribution of the RS3, a rotatable square setup is a must to ensure even tire wear at all four corners. Shedding unsprung weight by downsizing to an 18" wheel will also improve upon the overall handling, braking, and acceleration characteristics of the car.

While 8V RS3 wheels are an important consideration once you already own one of these cars, there are quite a few other things to consider before purchasing an 8V RS3. Piston Heads wrote up a great used buyers guide for the 8V RS3, which highlights a lot of things to look out for while on the search for your ideal example.

SM-10 Specifications

Reproductive Harm - www.p65warnings.ca.cov

Reproductive Harm - www.p65warnings.ca.cov SM-10 features

The Flow Form Advantage

Flow forming enables us to create high performance wheels without the price premium of forging. It improves the mechanical properties and grain structure of the barrel, increasing its strength and stiffness, which allows us to use less material and reduce weight. Thanks to our superior engineering, our flow formed wheels have a higher load rating than some competitors' forged wheels.

"I" Beam Spokes

One of the most prominent features of the SM-10 is its advanced "I" beam spoke machining. Any excess material that doesn’t add strength is carved out from the sides of the spokes using a precision CNC ball cutter. This process is often deemed cost-prohibitive by others, but for performance without compromise we believe it's essential.

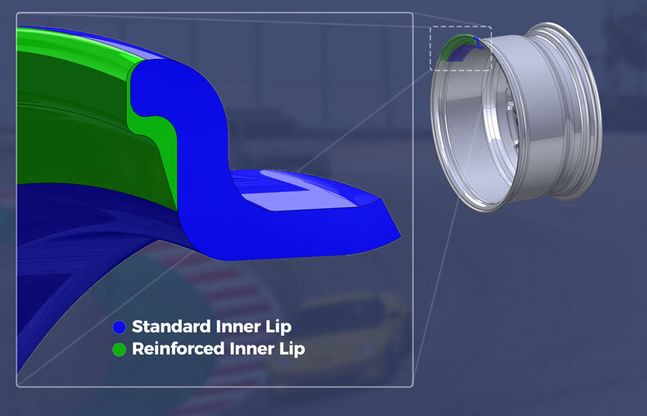

Bigger, Tougher Inner Lip

The inner lip is the most vulnerable part of a wheel because it has no spokes for support. Our Flow Formed Evolution line adds more material to this high-impact area as an extra layer of protection against track berms, potholes, and whatever else the road may throw at you.

Maximizing Concavity

We use the deepest concave face profiles we can for every application after factoring in critical clearances such as brake calipers. The SM-10 utilizes 3 unique profiles to make this possible, with the deepest concave face delivering reduced weight and a stunningly aggressive appearance.

Big Brake Clearance

Big brakes often require bigger, heavier, more expensive wheels, which aren’t ideal in a performance environment. The SM-10 is one of our many wheels which solve this problem. Through comprehensive laser scanning and endless rounds of test-fitting, we’ve created 18” wheels to clear huge brakes that typically require 19” wheels from other manufacturers.

Weight Optimized

We conducted extensive Finite Element Analysis (FEA) to reinforce high-stress areas and to remove material where it didn’t improve strength. The result is a wheel that is exceptionally light without the strength compromises found on typical lightweight wheels.²

Built for Impact Sockets

Track wheels need track tools. Don’t settle for wheels that require undersized tuner lugs or thin walled sockets. All Apex wheels accommodate over-sized race lugs and impact sockets to make swapping wheels lightning fast.

32mm

Socket Diameter Clearance

Finishing Touches

The SM-10 is finished using a multi-stage liquid paint over a powder coated base coat. This coating process leaves lug holes, center bores and mounting pads untouched, which ensures proper fit and torque values.

JWL and Beyond

All Apex Flow Formed wheels meet or meaningfully exceed JWL load rating requirements. Some manufacturers don't meet the minimum requirements, yet still claim to be compliant. Always compare load ratings to ensure you aren’t sacrificing critical strength for a slightly lighter wheel.

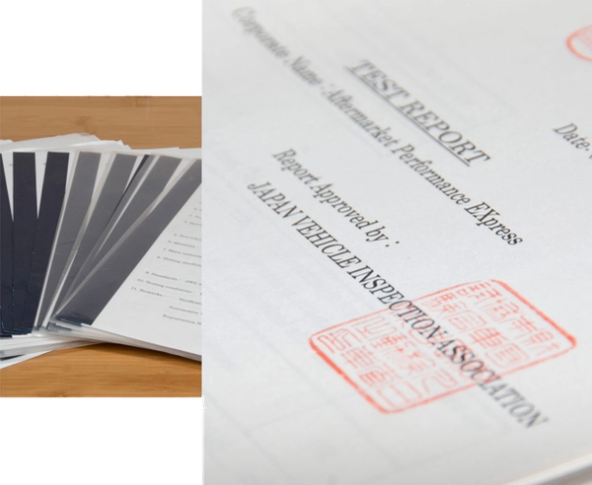

True VIA

The VIA is an independent wheel testing and auditing agency similar to TÜV. Many companies falsely claim their wheels have been certified, and even use the VIA stamp without permission. Our Flow Formed wheels have been certified, and we provide the registration numbers for every wheel. Protect yourself. Demand registration numbers from manufacturers.

Additional features

Hub Centric

All SM-10 wheels are purpose built for select vehicle applications. Very few applications require centering rings.

Center Caps

All Apex wheels come with our gloss black cap included that is interchangeable with the OE cap. We also offer additional colors for select fitments.

Wheel Hardware

Apex wheels can be used with all OEM mounting hardware, proper aftermarket hardware and most wheel spacers. Wheel locks and stud conversion kits also work perfectly.

TPMS

All Apex wheels accept OEM and aftermarket Tire Pressure Monitoring Sensors and standard fit valve stems. If you don’t have sensors, then select from our metal stems available in multiple finishes.

REAL DRIVERS NEED REAL PERFORMANCE.

Not all claims of performance are backed up by facts—and it's a big problem. Don't get sold fashion when you want function.

A Wheel You Can Depend On

Accidental Damage Replacement

Curb rash or pothole damage on the street? Make an oopsie at the track? We’ve all been there. Apex is proud to offer 50% off replacement wheels, no matter the damage.

Lifetime Warranty

All Apex wheels come with a lifetime structural warranty against defects in workmanship and materials, plus a 1 year finish warranty. Exchanges are fast, easy, and hassle-free.

Footnotes

¹ All wheels compared with equivalent 18x10” ET25 5x120mm / 72.56mm fitment. Price displayed based on MSRP as of 5/16/2025.

If you like cheap gear you will hate this newsletter.