Bolt Pattern & Centerbore Guide: What They Are and How to Measure Them

Article | 05/06/2025 by Tom Maloney

Updated on 11/04/2025

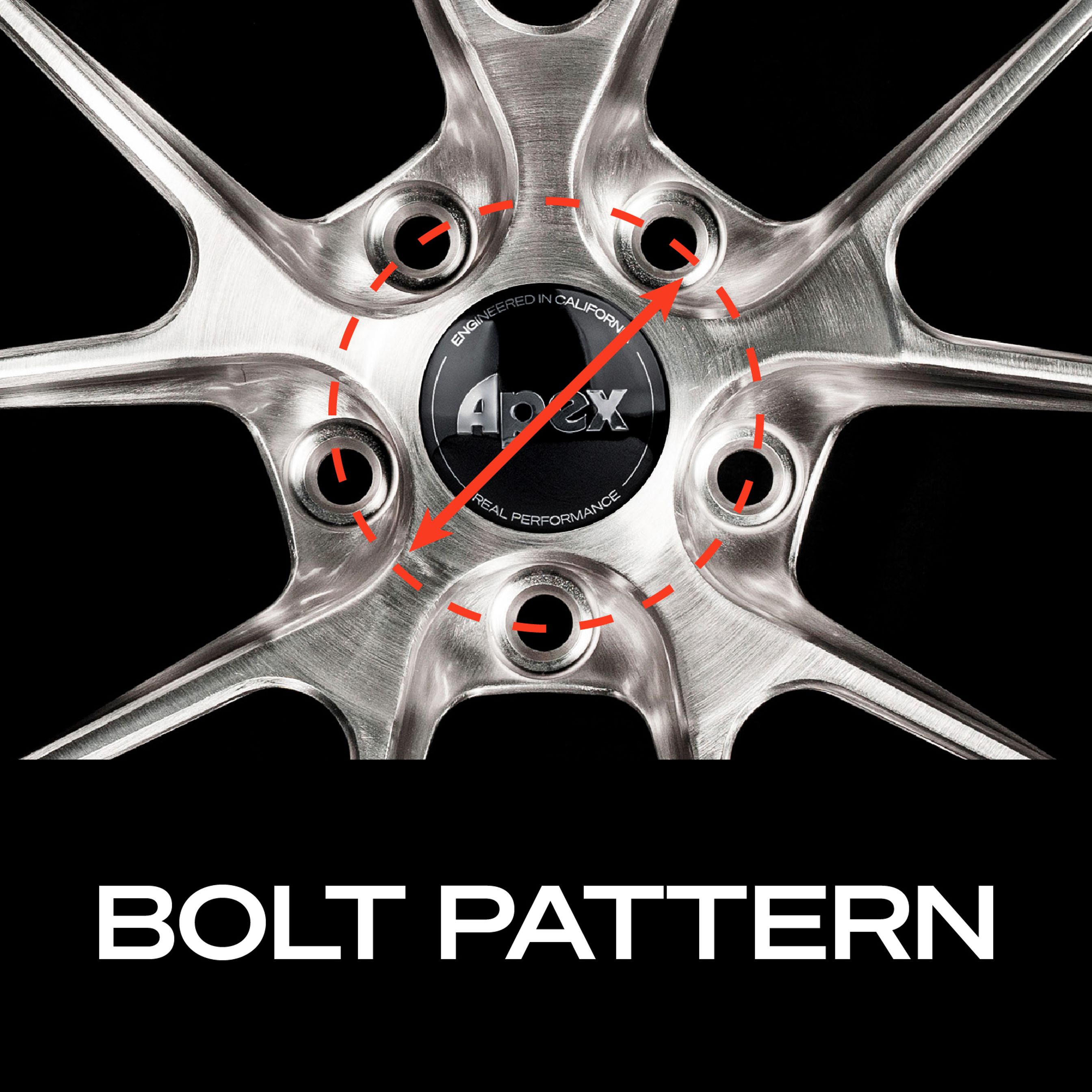

A wheel’s bolt pattern, which is also referred to as its pitch circle diameter (PCD) or lug pattern, is the diameter of the circle formed by the studs/bolt holes on a wheel. This diameter is measured as if the circle passes through the center of each of those bolt holes, as illustrated above. Bolt patterns are typically displayed using two numbers like 5x120mm or 4x100mm. The first number is the number of mounting holes on the wheel. The second number is the measurement found between two points of a circle centered within those stud or bolt holes. The way that’s measured is illustrated in the image above by the line with the arrows. If a car has a 5x120mm bolt pattern and centerbore, it has 5 lug holes and a 120mm lug circle spacing. That second measurement can be presented in either millimeters (5x120mm) or inches (5x4.5”), but most modern passenger cars use millimeters. All Apex wheels use millimeters for their bolt pattern, however trucks, offroad or heavy-duty work vehicles, and some older domestic vehicles may use inches.

A wheel’s centerbore is the diameter of the internal bore on the backpad of the wheel. It is designed to fit the vehicle’s hub ring and allows the wheel to index onto the hub prior to hardware being installed. Knowing this measurement is critical as different manufacturers will often share an identical bolt pattern, but use different centerbores. Hardware called centering rings can be used if the wheel’s centerbore is larger than the vehicle hub ring’s outer diameter by making up the difference between the hub’s outer diameter and the centerbore’s inner diameter, which will retain what’s known as a hubcentric fit.

Bolt Pattern Compatibility and Safety Considerations:

Running the correct bolt pattern and centerbore specifications is critical for both safety and compatibility reasons. For starters, trying to mount a wheel with the incorrect bolt pattern or centerbore will often prevent you from mounting the wheel altogether. However, smaller differences in a wheel’s bolt pattern or lug seat type, which may not prevent you from mounting the wheel, can lead to vibrations and eventually wheel hardware loosening/falling off while driving, or premature hardware failure. In the worst-case scenario, these problems can cause a wheel to detach itself from the vehicle while driving. As such, knowing the correct wheel specifications for your car is absolutely crucial if you’re swapping your wheels from stock, not just for aesthetics or performance, but for safety.

How to measure Bolt Pattern and Centerbore:

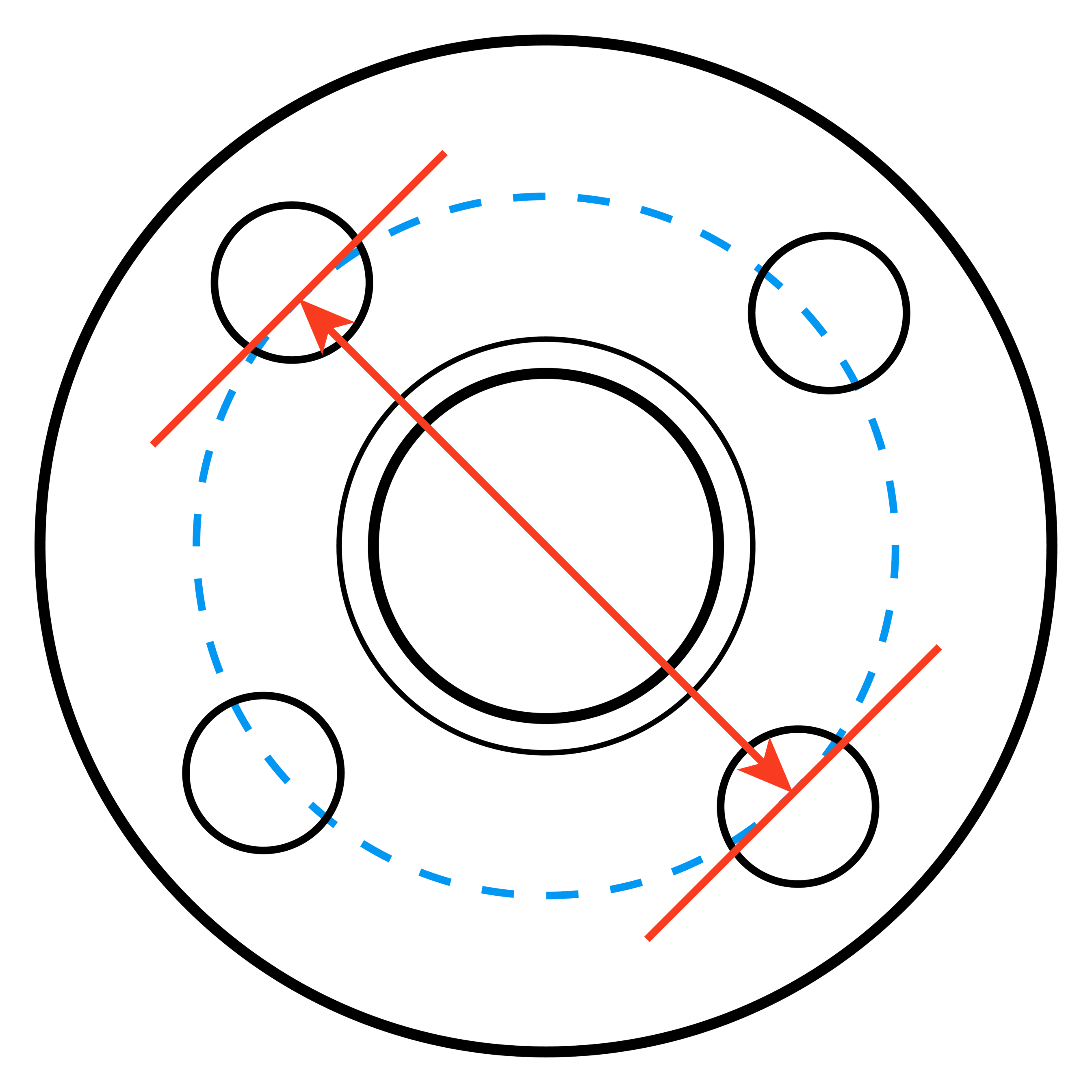

Measuring a bolt pattern is a simple enough task when the number of bolt holes is even. A 4x100 bolt pattern can be measured by measuring from the center of a lug hole on a wheel across to the center of the opposite hole. This method can be applied to any other bolt pattern with an even number of lug holes (IE: 4 lug, 6 lug, 8 lug).

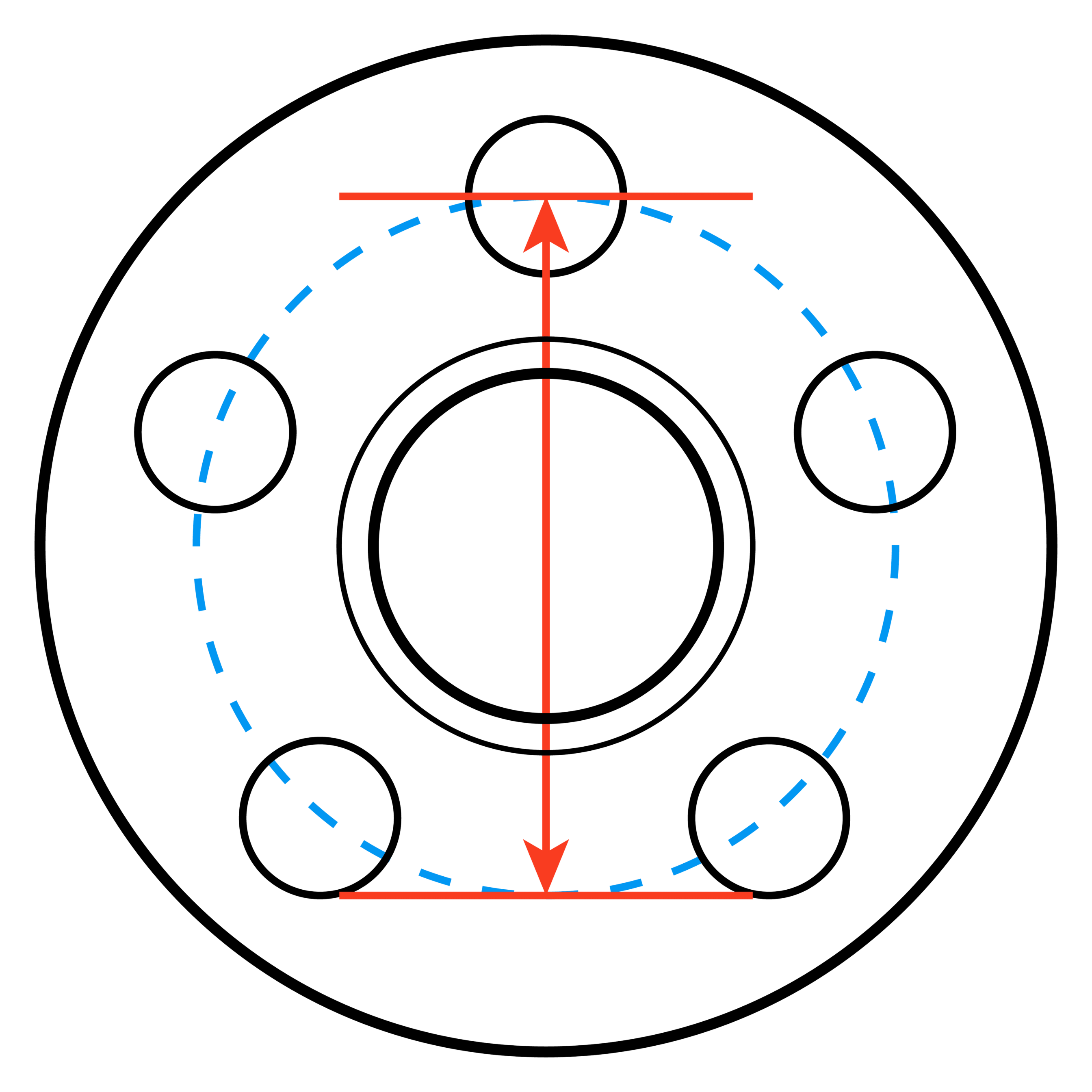

5-Lug wheels can only be accurately measured by using a specialized tool called a bolt pattern gauge. However, you can approximate a 5-lug bolt pattern by measuring from the center of one lug hole to the center of the line drawn between the two opposite lug holes at their outer diameter. You can see how to measure this in the diagram below. Note that this method of measurement is not exact, and many 5-lug bolt patterns are very close to each other – sometimes within margin of error. If you know your vehicle’s chassis data, referring to a bolt pattern chart will be a much more consistent way of identifying its wheel specifications.

The good news if you found measuring the bolt pattern a little confusing is that measuring the centerbore is much simpler and can be done relatively accurately with a ruler. That said, a telescoping bore gauge will be more accurate. You’ll want to be sure you check the true centerbore of the wheel, not just the chamfered portion of the centerbore hole that extends for the first 3-5mm into the hole from the back of the wheel face.

Cross-Brand Compatibility, Centering Rings, and Hubcentricity

Many brands and vehicle models share the same bolt pattern. However, while having a shared bolt pattern is required for wheels made for one manufacturer’s vehicles to be compatible with those from another, a shared bolt pattern alone does not guarantee that those wheels will work. Often, two vehicles with a shared bolt pattern will have different types of lug seat, which will require alternate wheel mounting hardware with the correct seat type to match the new wheels. Running mismatched lug seat specifications can reduce how effectively you can torque the lug bolts or nuts down, which can lead to serious major safety issues.

- If the hub ring of the vehicle is larger in diameter than the centerbore of the wheel you’re trying to run, your only options to mount the wheel is to enlarge the centerbore of the wheel by machining it or use adapter-spacers. Both options can compromise the safety of the wheel assembly on the car either by weakening the wheel’s back pad due to overboring it or introducing additional failure points with an adapter spacer.

- If the hub ring of the vehicle is smaller than the centerbore of the wheel, a part called a centering ring can be inserted into the wheel’s centerbore to reduce its diameter. These rings are typically made of aluminum and have an inner diameter that matches the vehicle’s hub ring, and an outer diameter that matches the wheels centerbore – with some minor allowance for installation and removal. A wheel that is built to mount on a car’s hubcentric ring as an exact fit is called a hubcentric wheel. Centering rings allow you to make wheels with an oversized centerbore hubcentric.

Despite the notes above, it is quite common for some customers to use either aftermarket or OEM wheels that were not originally intended for their vehicle by its manufacturer. Common examples of this with Apex forged wheels and flow-formed wheels include 5x120mm BMW wheels being used on Camaros, Cadillacs, Pontiacs, and certain Honda/Acura models. Likewise, it is common for our 5x114.3mm Mustang wheels to be mounted on a wide variety of JDM chassis and for other 5x114.3mm JDM wheels to be interchanged between JDM chassis. While all of these interchangeable fitments require centering rings and some require different wheel hardware, they open up the wheel options available for these cars substantially.

Lastly, and probably the most important and misunderstood part of wheel compatibility, is wheel fitment. All of the factors we’ve discussed in this article are important, but the aforementioned are only what’s required to bolt the wheels onto the car. Confirming that the wheels you want to run have the correct diameter, width, and offset is critical to ensuring they fit within your vehicle’s fenders correctly, and knowing those measurements is necessary to select tires that are ideal for your particular application and clear your car’s suspension components. In addition to the basic elements of fitment, the design of the wheel plays a role in its brake clearance, which is another critical factor for compatibility.

Luckily, we’ve taken the guesswork out of wheel shopping. Apex’s wheel and tire fitment guides guide you through what is required for your next set of wheels, including whether centering rings or aftermarket hardware is needed.

Bolt Pattern and Centerbore Charts:

Bolt Pattern charts are a useful way to identify the bolt pattern for specific vehicle manufacturers and chassis. Apex also provides in-depth guides on manufacturer and model specific bolt patterns focused on enthusiast chassis. Take a look at these charts on our manufacturer specific bolt pattern articles here:

BMW Bolt Pattern and Centerbore Guide

Porsche Bolt Pattern & Center Bore Guide

Chevrolet Bolt pattern & Centerbore Guide

FAQs About Bolt Patterns and Centerbore:

We often get asked a number of questions about bolt pattern and centerbore repeatedly. Here are some of the most commonly asked questions:

- What is the most common 5-lug bolt pattern?

The most common 5-lug bolt pattern is arguably 5x114.3mm (AKA 5x4.5”). This bolt pattern is used across a wide range of Japanese auto manufacturers including Honda, Toyota, Nissan, Mazda, and Mitsubishi. It is also used on a variety of Ford and Chrysler vehicles.

Other Common 5-lug bolt patterns include:

- 5x112mm, which is commonly found on European cars like Audi, modern BMWs, Mercedes Benz, and VW.

- 5x120mm, which is commonly found on older BMW, some General Motors vehicles, and select newer Honda/Acura models.

- 5x100mm, which is commonly found on older Subarus, VWs, and Toyotas.

- Are bolt patterns interchangeable?

Bolt patterns can’t easily be altered or changed without compromising either the wheel hardware or using an adapter-spacer or a more costly hub conversion.

- Can I change my car’s bolt pattern?

Bolt patterns can be changed, but the process can be a costly one depending on the car. Typically, this requires swapping out the hub assembly and replacing wheel bearings. Such conversions are commonly used to go from an older bolt pattern standard to a newer bolt pattern, such as going from 4x100mm or a 4-lug to a 5-lug wheel. This is often done to open up additional wheel options in other fitments or diameters, as well as accommodating larger brake packages.

- Can you drive with the wrong centerbore?

Mounting and driving on a wheel with the incorrect centerbore is only possible if the centerbore of the wheel is larger in diameter than the hub ring mounting flange diameter. Ideally the centerbore would match the hub ring and provide a “hubcentric” wheel fitment. This means that the wheel rests on the hub and is indexed onto the hub firmly, allowing wheel hardware to be installed/torqued down without having to support the weight of the wheel. Wheels with an oversized centerbore can have issues with vibrations and wheel hardware failure due to the wheels not being fully seated if care is not taken when torquing the wheels after installing them. Running wheels with oversized centerbores is common when using wheels from other manufacturers or vehicle models on a different vehicle with the same bolt pattern. Centering rings can be used to take up this gap and make a wheel hubcentric for certain applications as long as they are sized correctly.

Tags

Tom Maloney

Tom MaloneyTom M.

Tom is a BMW Fitment Expert at APEX Wheels. Prior to joining the company in 2019, he worked for BMW of North America as Fleet Manager: Portland (OR) for the ReachNow car-sharing program, and as Warranty Administrator/Loaner Fleet Manager at BMW Portland. In addition, Tom has extensive training in BMW TSBs (Technical Service Bulletins) as well as in-depth knowledge of all BMW chassis and their wheel fitment options, with and without aftermarket brake and suspension upgrades. His high-performance driving experience includes autocross events in southern Oregon and track days at PIR in his 2004 E46 330i with 17x9 ET42 APEX ARC-8 wheels. Vehicles he owned prior to indulging his passion for BMWs include a 1989 Jaguar XJ6 and a 2006 S197 Ford Mustang. Fun Fact: Tom is a huge Formula 1 fan. Have questions about wheels for your BMW? Use our contact form and ask for Tom.

If you like cheap gear you will hate this newsletter.