What are the Differences Between the VS-5 and the VS-5RS?

Article | 04/28/2025 by Tom Maloney

Updated on 11/14/2025

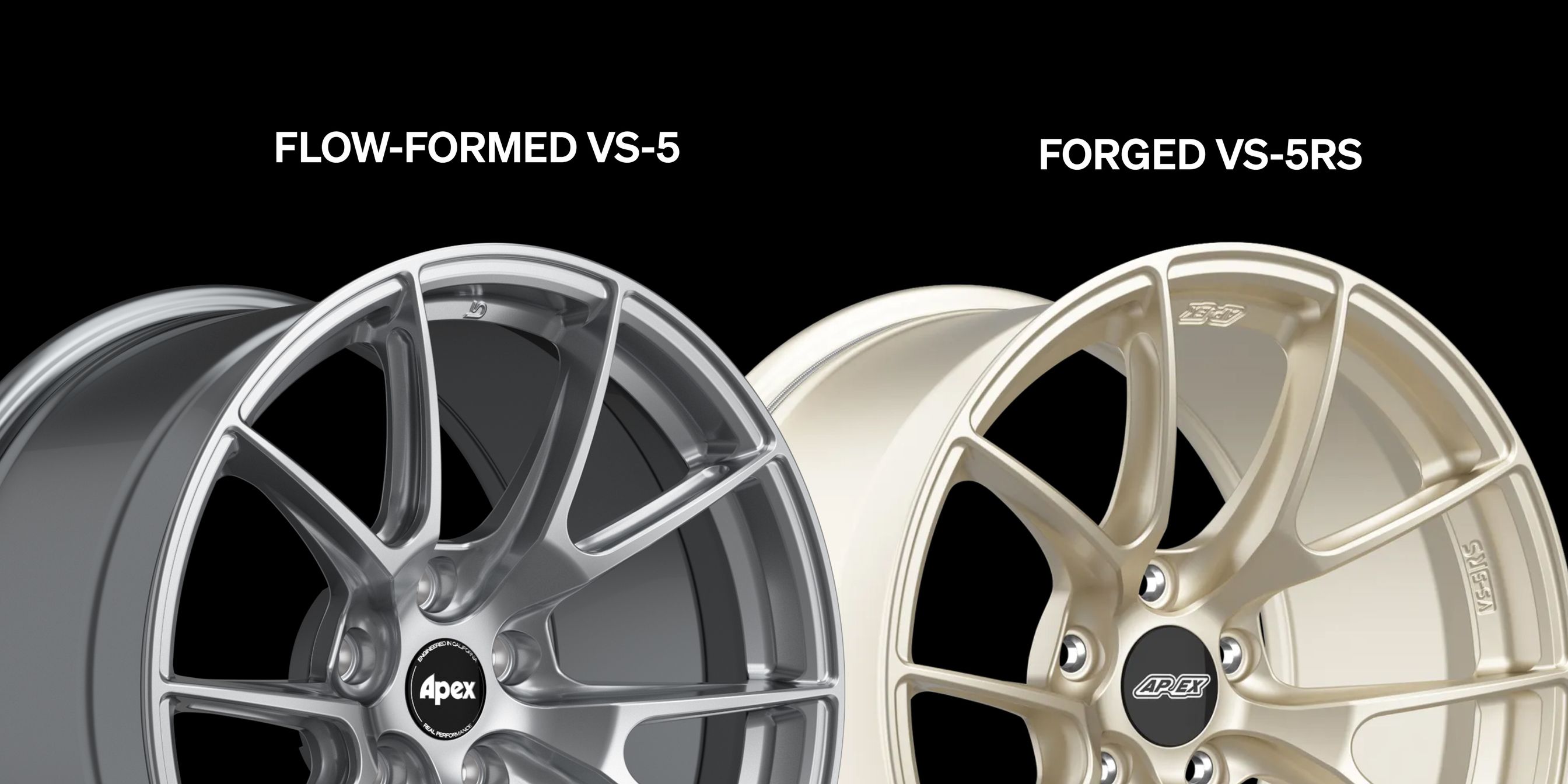

In this article, we explore the key differences between the flow-formed VS-5 and the forged VS-5S to help you decide which of Apex’s most popular split 5-spoke designs is the right choice for your application.

| VS-5 | VS-5RS | |

|---|---|---|

| Construction | Flow-Formed | Forged |

| Weight | 18.6-23.7 lbs depending on size | 16.3-21.1 lbs depending on size |

| Price Point | $379-$529 per wheel | $629-$949 per wheel |

| Load Rating | 1600 lb | 1600 lb |

At Apex, we strive to engineer high-performance wheels for everyone. We make fitments for an incredibly diverse range of platforms, but we also consider a wide range of applications and budgets when adding new wheels to our offerings. When it comes to our iconic split 5-spoke design, which was first introduced with the forged VS-5RS, we now actually produce four unique variants. Part of how we bring Real Performance to as many drivers and price points as possible is producing several designs in both fully-forged and flow-formed variants. When engineered properly, both of these construction techniques can produce true high-performance, competition-grade wheels. Understandably, having four versions of a split 5-spoke wheel can make things a little confusing when deciding which one is right for your application. In this article, we’re going to look at these four different split 5-spoke offerings and specifically compare the two most commonly cross-shopped variants, the forged VS-5RS and the flow-formed VS-5.

All in the Family

Of our four different split 5-spoke wheels, the flow-formed VS-5 and the forged VS-5RS are the wheels best suited for most applications. We produce two additional forged variants of this design and both are relatively specialized: The VS-5RX and the VS-5RE.

The VS-5RX is part of our Touring Line and is a lightweight, high-performance wheel that is optimized to handle the heavier load rating requirements of modern SUVs and EVs. It’s produced in fitments tailored specifically for those vehicles.

The VS-5RE is part of our Enduro Line and is our strongest motorsport-optimized wheel. It was engineered for heavier race cars and track builds that run aggressive aero setups, which can create a lot of downforce and require a wheel with a higher load rating to maintain performance. Its higher load rating is also beneficial for certain track cars that run extremely sticky R compound tires, which can have a big impact on how much strain is placed on a wheel in competition. If you’re unsure if the VS-5RE or the VS-5RS is the better forged option for your application, reach out to one of our fitment experts here.

Iconic Look. Iconic Performance. Different Construction.

Choosing between the VS-5 and the VS-5RS is a little trickier. Both are legitimate high-performance wheels, but are made using different construction techniques and have significantly different price points. The VS-5RS is a fully-forged wheel and the VS-5 is a flow-formed wheel. Both of these wheels are truly track-worthy. However, the forged VS-5RS represents the pinnacle of Apex’s offerings when it comes to performance. As part of our Sprint Line, the VS-5RS was designed with a focus on being optimized for weight-savings and with an extremely rich feature set focused on maximizing performance. The VS-5RS is going to outperform the flow-formed VS-5 in some key areas and is ideally suited for the driver that’s seeking to squeeze every last ounce of performance out of their build. The VS-5RS’ ultra-high performance profile and forged construction comes at a higher cost that may push it out-of-budget for some enthusiasts.

When we created the flow-formed VS-5, we did so with the intention of making a wheel that not only delivered the same design language of its forged sibling, but pushed the maximum performance possible out of a flow-formed wheel at an incredible value. With almost two decades of experience producing flow-formed wheels, we knew exactly how to engineer the VS-5 to achieve that, and at nearly half the price of its forged sibling, VS-5 delivers. It’s a wheel that brings many functional features to the flow-formed category that are typically only found on forged wheels. While the VS-5 isn’t quite going to match the performance of its forged counterpart, it is an impressive wheel that we consider the last step in flow-formed performance before leveling up to a forged option. So, how exactly do the two wheels stack up against each other?

By the Numbers

Weight-Savings: A well-engineered forged option will deliver the maximum combo of weight-savings and strength. While a well-engineered flow-formed option can be a remarkably strong and lightweight wheel – and can even outperform a poorly engineered forged option in some cases – the forged VS-5RS is a lighter wheel than the flow-formed VS-5. In this case, the VS-5 is between ~2-3 lbs heavier than the forged VS-5RS in most fitments. For example, the VS-5RS in an 18x10 ET25 fitment weighs 18.5 lbs, while the VS-5 in the same fitment weighs 21.3 lbs. While the flow-formed wheel offers respectable weight-savings to stock wheels and many of the other flow-formed options on the market, those looking for maximum weight-savings will want to opt for the VS-5RS.

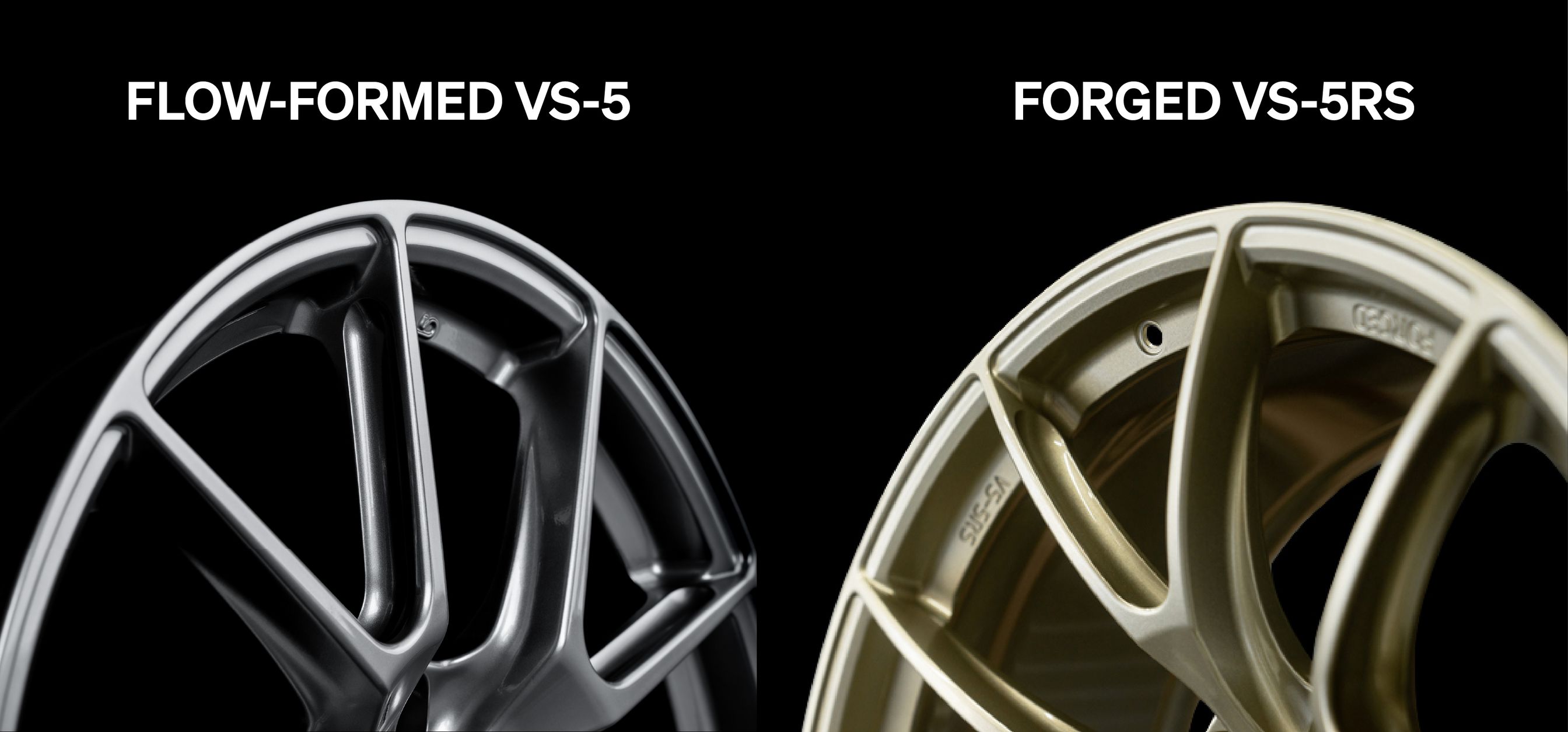

Aesthetics: Despite how strikingly similar these wheels look, they have some aesthetic differences as a byproduct of their different construction techniques. With the forged VS-5RS, we can dial-in tailored face profiles for each fitment we make. This allows us to make a wheel with the absolute maximum concavity possible for a given platform. With flow-formed construction, we use 3 specific face profiles across all fitments, which allows us to produce this wheel for a wide range of platforms while keeping it at a price point that maximizes performance-for-money. While those 3 face profiles were designed to deliver max concavity, some fitments will sacrifice a bit of concavity relative to their forged counterpart. Additionally, forged construction allows us to create thinner, deeper spokes without compromising any of the wheel’s strength and stiffness, and the VS-5RS has spokes as thin as 2.4mm at their thinnest point. Because of the nature of flow-forming, the VS-5 has to be thicker in some areas in order to closely replicate the forged design. This means slightly thicker spokes and a less-defined, “chubbier” look than the forged version. There’s also a difference in spoke depth between the two wheels; because we use custom motorsports blanks for our forged wheels, we can create a remarkably deep spoke at 41mm, which allows us to maximize the wheel’s weight-savings while also allowing us to maximize spoke stiffness. The flow-formed wheel has spokes that are around 25mm deep.

Additionally, we’ve reintroduced our dynamic Hyper Black finish on the flow-formed VS-5. This is the first wheel to feature this finish outside of the legendary ARC-8, and it is not available on the VS-5RS at this time. If that finish is a must-have for you, the flow-formed VS-5 is your wheel.

Flow-Formed VS-5 Profiles

Strength/Load Rating: The flow-formed VS-5 and the forged VS-5RS both boast an impressive 1,600 lb load rating, and both wheels were tested to meet or exceed stringent JWL standards by 50-200%. However, the forged VS-5RS is one of the most uncompromising wheels we make and as a fully-forged offering, we don’t just want to know it exceeds JWL standards – we want to know just how far it needs to be pushed to fail – even if that is extremely far beyond the rigors of any typical use case. As such the VS-5RS is subjected to more rigorous independent testing, which is carried out and certified by Standard Testing Labs (STL). You can read more about Apex’s independent testing practices here. The VS-5 was also tested to exceed JWL requirements and is more than strong enough for serious track use, however the forged option may fare better when it comes to impacts like those you may encounter going off-track or battling in-the-pack during intense racing. This makes it the better option for serious competition drivers with cars that will exclusively see track time. Fortunately, both are covered by our legendary Wheel Replacement Program and one of the best warranties in the industry, so you can race without fear…at least about having to replace a wheel.

Flow-Formed VS-5 Brake Clearance

Brake Clearance: Another important factor for high-performance wheels is brake clearance. Both the VS-5 and the VS-5RS offer excellent clearance, and both feature a 0-degree draft barrel to maximize brake caliper clearance. This is an exceptionally rare design feature to find on a flow-formed wheel! However, because forged construction allows us to strategically remove more material from a wheel’s spoke design and to tailor a wheel’s spoke profile for specific cars and effectively “shrink-wrap” the spokes around their brake, the forged VS-5RS generally offers a bit more brake clearance in many fitments.Consulting our comprehensive fitment guides or reaching out to our fitment experts will clarify which wheel will work best, and is especially important if you’re running an aftermarket big brake kit or plan to upgrade to one at some point.

Performance Features: Something that sets the VS-5 apart from many other flow-formed wheels on the market is the number of features we incorporated in its design that are typically only found on forged wheels. These features include aggressive, side-milled spokes that provide significant weight-savings and a reinforced inner lip for durability and strength at the wheel’s most vulnerable point. The VS-5 was also designed to accommodate oversized race lugs and impact sockets, so swapping wheels at the track is easy. Of course, you’ll find those features the VS-5RS as well, and while the VS-5 has a reinforced inner lip that makes it exceptionally strong for a flow-formed wheel, the forged wheel features our superior Sprint Spec design with a unique channel profile that makes it exceptionally durable on-track, particularly when it comes to impacts.

Center Caps: This is the last area where these two wheels differ from each other. The forged VS-5RS offers OEM center cap compatibility in every fitment we produce the wheel in. Due to the limitations of manufacturing flow-formed wheels, we chose to produce the VS-5 in two popular OE cap sizes that mirror BMW or Mustang dimensions, depending on the size of wheel. However, each of these wheels look fantastic running our colored Apex-branded center caps and we make every color in our center cap range for those sizes.

Tags

Tom Maloney

Tom MaloneyTom M.

Tom is a BMW Fitment Expert at APEX Wheels. Prior to joining the company in 2019, he worked for BMW of North America as Fleet Manager: Portland (OR) for the ReachNow car-sharing program, and as Warranty Administrator/Loaner Fleet Manager at BMW Portland. In addition, Tom has extensive training in BMW TSBs (Technical Service Bulletins) as well as in-depth knowledge of all BMW chassis and their wheel fitment options, with and without aftermarket brake and suspension upgrades. His high-performance driving experience includes autocross events in southern Oregon and track days at PIR in his 2004 E46 330i with 17x9 ET42 APEX ARC-8 wheels. Vehicles he owned prior to indulging his passion for BMWs include a 1989 Jaguar XJ6 and a 2006 S197 Ford Mustang. Fun Fact: Tom is a huge Formula 1 fan. Have questions about wheels for your BMW? Use our contact form and ask for Tom.

If you like cheap gear you will hate this newsletter.